Work Session Status Week Ending 10/15 /2016

October 17, 2016

October 17, 2016

It has been a while since I’ve submitted a work progress report. Both Gail and I have had medical issues and surgery over the last month. I had assumed (guess that’s a bad assumption on my part) someone else would keep everyone informed, but it didn’t happen. I’ll do my best while convalescing to continue on with the progress reports on a more regular basis.

Not all of our projects are physically on the locomotive. Equipment needs maintained as well as various improvements to our work area.

Workers have been working on the car mover “Lurch” R & R the air brake compressor and dealing with various oil leaks.

We have also been working on the cold-start compressor, setting it in place along with it’s storage tanks. The unit had to be rewired to the electricity available on our site. Evidently some switches were bad and were needing replaced. We have however been able to manually control it to use it to air test the boiler. Associated piping and filters are being fit up.

Another non locomotive project has been fabricating a dolly to transfer the heavy superheater bundles from the storage containers to the hydro test stand and back.

The machine shop has been designing and fabricating a device to hold the throttle valves steady while being lapped to their seats. Also they were drilling the precise bolt holes in the new dual sided boiler pressure gauge face plates and installing sleeves in the bolt holes.

The custom made face plates are now ready to be mailed off to be reunited with the rebuilt and certified pressure gauge.

We are still dealing with leaky flexible staybolt caps but are close to putting an end to those troublesome plugs and washout plugs. We have, hopefully, one more sleeve to be removed and replaced.

While reviewing our ultra sound measurements of the firebox we discovered two areas inside the firebox which were above minimums in metal thickness, but we decided to do some build-up welds in those two areas.

The radial buffer brass overlays are in poor condition and are being prepared for a new application of brass bearing surface.

Sander check valves have been installed along with their respective sander pipes for the drivers.

The on-going work of piping up the various 26L air brake components is progressing steadily. Many of the lines are custom lengths and require them to be ordered.

There will be a New Member Orientation on October 29th at 9:00 AM sharp in the Reefer Office. Many of you new members that are interested have more than likely been contacted by Jon Spargo our Chief Safety Officer by email.

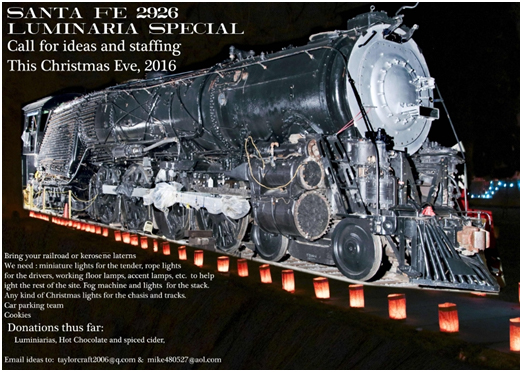

The below photo has some info on it if you will blow it up and read it you will see we are trying to put together a Christmas Lighted and Luminaria Train for Christmas Eve. Obviously a lot of the work will have to be done ahead of Christmas Eve, but if you can help us decorate her possibly the week of, or donate some lights and help with setting the luminarias up it would be very much appreciated. This is just in the planning stages at this time and anyone that can help can contact Ron Taylor or Dr. Mike Hartshorne as per his photo and email there. We’ll also set up a sign-up sheet for people to volunteer to help. We think this would be something great to try and maybe it will go on the City’s Luminaria Tour as well. Wouldn’t that be grand!

Hope everyone has a great week, and as always . . .

Keep on Steamin’,

Rick Kirby, CMO

NMSL&RHS